Chengdu Gute Machinery Works Co., Ltd.

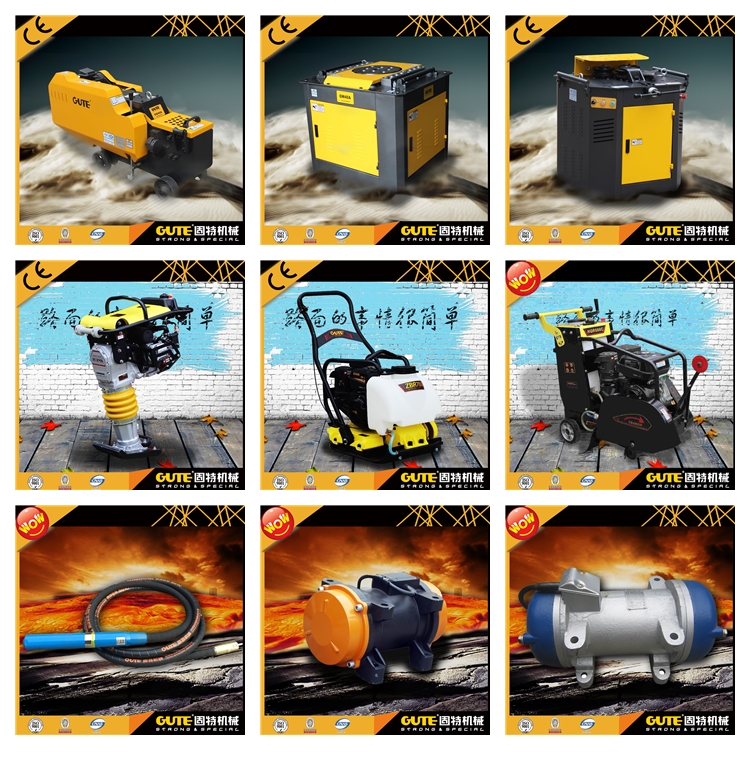

Chengdu Gute Machinery Works Co., Ltd. is a professional

manufacturer producing world-class steel processing products for

building industry and concrete products for road industry. Located

in Chengdu city of China. Gute Machinery has 26 years history and

has been involved in a wide variety of construction projects at

home and abroad.

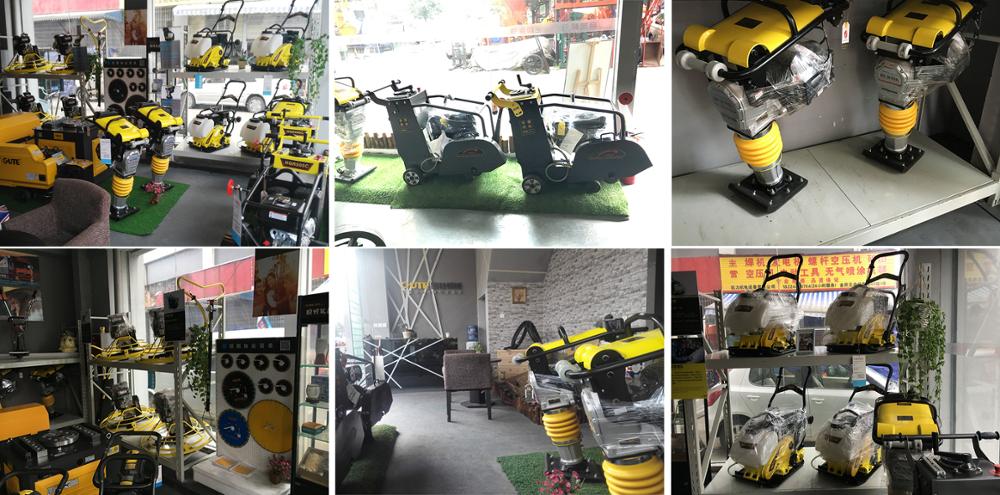

Our domestic strong marketing service team has established more

than 50 GUTE showrooms. We have high density in the domestic market

coverage.

With “integrity-based, customer first, quality first” principle,

GUTE machinery has established a high quality after-sale team. It

is free for 24 hours to provide customers with free door-to-door

guidance,make solutions, and free installation. For overseas

customers, GUTE machinery will also make visit for providing

support and solutions based on customer needs and suggestions.

--------------------------------

Certificates

----------------------------------------